Guided tour

Besides distributing colour printing solutions, Tasco has an entire production of blank labels on rolls. Supplying the best label printers in the market is only sufficient if it is accompanied by extremely high-quality label materials that can be delivered quickly. By taking label production in-house, we assure our customers of consistently high quality and on-time deliveries.

Materials carefully selected

Our production process starts from our large warehouse. This is where the master rolls arrive, which are blank rolls that we have not yet processed. Continuously glued in one piece with different compositions, coatings and glue strengths. All these rolls come together in Gavere, where we keep large stocks. This allows us to produce orders at any time.

Continuous role conversion

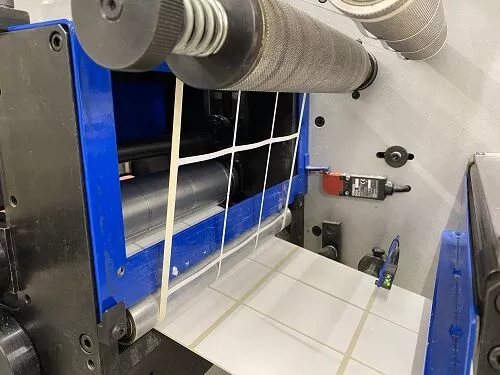

After the warehouse, our rolls are placed on one of our three rotary die-cutting machines. Tasco uses the Daco DTD 250R, this punching machine uses a metal form, called a punch, which is placed on a cylinder. The material passes through the machine and the punch presses its imprint into the material each time. Deep enough to cut the material but not too deep so as not to push through its support.

Die-cutting in all shapes and sizes

Tasco carefully stores all its die-cuts. Our customers can rest assured that when they place the same order they will receive the exact same size and shape. Tasco has a service where we will produce more than 50 formats all the time. For these standard formats, our customers enjoy blank rolls with no die-cutting costs. Punches can be very expensive and have a certain lifespan. If you as a customer want a special format, at Tasco we do not charge the full cost of the die-cutting but a fixed contribution for a customised production with every order, regardless of the order quantity and regardless of the cost of the die-cutting.

Waste removing and roll slitting

After die-cutting, the waste is removed from our roll and the roll can be slit once more (using one or more blades) to end up with several separate rolls of blank labels.

Pack and ship or keep on stock for a while longer

When production is complete, each roll is individually wrapped so that when it goes into your or our stock your rolls are well protected from the outside world.

Home » Our labelproduction

Our labelproduction

Watch our video through the production

1. Materials carefully selected

Our production process starts from our large warehouse. This is where the master rolls arrive; these are blank rolls that we have not yet processed. On one piece of continuous glued material with different compositions, coatings and glue strengths. All these rolls come together in Gavere and we keep them stored here in large stocks. That way we can produce orders at any time.

2. Converting rolls to die-cut labels

After the warehouse, our rolls are placed on one of our three rotary die-cutting machines. Tasco uses the Daco DTD 250R, this punching machine uses a metal form, called a punch, which is placed on a cylinder. The material passes through the machine and the punch presses its imprint into the material each time. Deep enough to cut the material but not too deep so as not to push through its backing.

3. Punches in all shapes and sizes

Tasco carefully stores all of its dies. Our customers can rest assured that when they place the same order they will get the exact same size and shape. Tasco has a service where we will produce over 50 sizes consistently. For these standard sizes, our customers enjoy blank rolls with no die-cutting costs. Punches can be very expensive and have a certain lifespan. If you as a customer want a special format, at Tasco we do not charge the full cost of the die-cutting but a fixed contribution for a custom production with every order, regardless of the order quantity and regardless of the cost of the die-cutting.

4. Waste removal and roll slitting

After punching, the waste is removed from our roll and the roll can be slit once more (use one or more blades) to end up with several separate rolls of blank labels

5. Pack and ship or still in stock for a while

When production is complete, each roll is individually wrapped so that when it goes into your or our stock, your rolls are well protected from the outside.