Inkjet technology

How does an inkjet printer work?

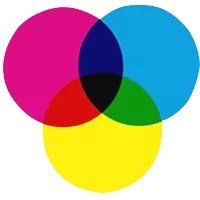

Label printers with inkjet technology make prints by spraying tiny droplets of ink in a particular pattern onto a carrier. This ink is stored in plastic capsules called cartridges. These cartridges are sold with a variety of ink colours. CMYK (Cyan, Magenta, Yellow, Black). An inkjet technology is an extremely popular and widely used way to print labels.

Very high print quality

An Inkjet technology is mainly used when you want to start working with beautiful photos and designs. Inkjet printing ensures that you can print very vivid and bright colours with your label printers and do so in very precise and fine juxtapositions. If you want high-quality prints at a low investment and price per label, an inkjet solution is ideal for you.

Maintaining the printhead

The print head is a highly technologically ingenious component of label printers with Inkjet technology The print head nozzles can be maintained in a few ways. To prevent the ink and print head from drying out, the printer is operated frequently under ideal conditions. As this is not always possible, there are cleaning cycles performed on the printhead on a regular basis. In the process, some systems will spray ink through the channels, resulting in a loss of ink. In this way, the wear of the printhead and thereby the printer itself is avoided for as long as possible. Tasco offers printing solutions where cleanings also take place but where no ink is wasted. In Tasco’s solutions, the printhead is semi-permanent and an easy and inexpensive replacement part of the printer. This ensures excellent print quality at all times and our labeler printers themselves have extremely long lifespans.

Types of inks

Water-based dye inks

Ideal for consumer products

You need labels to stand out in the supermarket or you want to go professional and boost your marketing. Dye ink is the ideal solution for you

Wider colour palette

You can add more colour in the dyes. Thus, the print produced is brighter and more vibrant. Because an inkjet system mixes the base colours, there is the possibility of producing ontelbnare colours.

Better print quality

Dye ink is much finer compared to other techniques. This allows for a much more precise print. This application is best for colour photos and graphics. Use an inkjet-coated material for the best results.

Pigment inks

Better resistance

Pigment ink does not dissolve. When the ink dries on the material, the pigment settles into the fibres. As a result, pigment ink has higher water resistance. Most of the molecules in pigment ink are hidden in the pigment particles. As a result, not all molecules are exposed to sunlight, making pigment ink more light-resistant

Modest yet colourful

Pigment ink is thicker. This makes it more difficult to make very fine prints. Pigment reacts differently to each coating. The best Tasco materials to print with this highly resistant technology is our matt paper or a PP material.

Perfect for industrial applications

Pigment ink is most often used for applications where legibility, resistance and strength are the main needs. Therefore, we often encounter this technology in sectors such as pharmaceuticals, soaps and detergents.

Inkjet solutions

Bekijk de verschillende inkjetoplossingen in ons assortiment

Legen Heirweg 59 Industrial Park Asper

Legen Heirweg 59 Industrial Park Asper  13 Rue Marie Poussepin 91410 Dourdan France

13 Rue Marie Poussepin 91410 Dourdan France